SAM PLASTIC ENGINEERING

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAM PLASTIC ENGINEERING

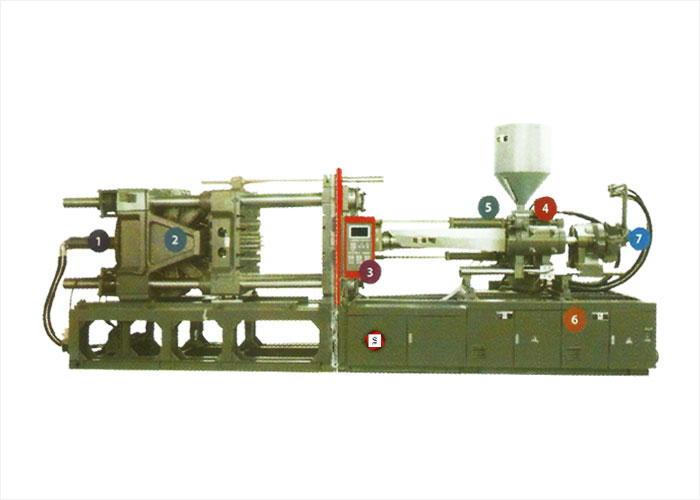

Plastic Injection Molding Machines

CONTROLLER

Sam machines are powered by latest PROGRAMMABLE LOGIC CONTROLLER from MIRLE, Corporation, Taiwan. The Controller employs a RISC 140 Mhz microprocessor, with response time of the closed – loop as 1-2 ms. The system HMI uses battery free MRAM to prevent moulding parameter loss. USB port on HMO Interface provides the ease of uploading data and taking screenshot of pages in BMP format for reference.

- 8.4” Colour LCD Screen with Alpha Numeric Keypad.

- All functional pages are user friendly.

- HOT-Keys for quick access function.

- Password and Data Lock Key to protect tampering.

- HMI with USB for data restore and back up function.

- Fast Setting Page shows Birds eye view of the Machine Operation.

- Parameter monitoring for last 100 cycles.

- Part Counters with Good / Bad Evaluation.

- Quality Record Pages of the last 20 Cycles.

- Track Record of Alarm Messages.

- Records the last 20 parameters changes.

- Display the Temperature, Injection and Cushion Curves for assessing the precision in molding.

- Automatic function for lubricating, purging and auto tuning of Temperature control.

- Analog / Digital Output facility for easy diagnosis.

- Uses W LAD programming which is easily customizable for user defined needs.

- Display the Temperature, Injection and Cushion Curves for assessing the precision in molding.

- Automatic function for lubricating, purging and auto tuning of Temperature control.

- Analog / Digital Output facility for easy diagnosis.

- Uses W LAD programming which is easily customizable for user defined needs.

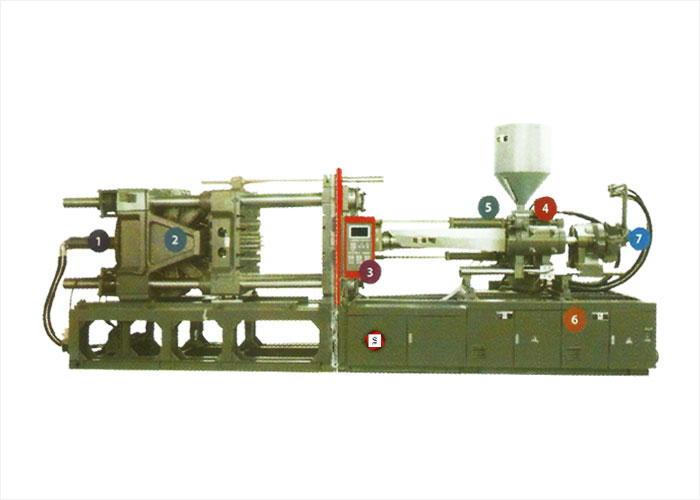

SYNERGY SERIES – THE UPPER EDGE

Our SYNERGY Series machine is powered by a Servo system and operates in a closed loop hydraulic system. The system integrates IMM Controller, Servo Drive and Motor, Internal Gear Pump, Encoder and pressure Transducer.

The Servo Drive takes analogue signals for Pressure (P) and Flow (Q) from the machine controller and a feedback loop is formed between the Drive Controller, Encoder and Resolver. Achieved P and Q data are matched against set data and any differences in resultant is immediately corrected thus forming a Closed Loop hydraulic circuit.

SALIENT FEATURES

Servo Drives

- User Friendly Operations.

- Ease of maintenance dude to

- Pluggable Modularity.

- Controller is equipped with an Intelligent

- PLC Module Controller.

- Uses Vector Control for maximum dynamic

- response.

- With response time of 125us, it makes motor

- response faster.

Servo Motor

- High Torque Accuracy

- High Speed

- Compact Design

- Durable

- Maintenance Free

Internal Gear Pump

- Longer life.

- High volume efficiency.

- Very low pump flow and pressure pulsation.

- Low noise level.

- Large speed range.

ADVANTAGES TO THE CUSTOMER

- Significant reduction in energy consumption and therefore energy costs.

- Excellent regulations characteristics.

- Integrated closed - loop control in converter, compensation for hydraulic non – linearities.

- Higher efficiency than a controller asynchronous motor with variable pump.

- Amortization of higher initial costs for Servo is offset by power saving within a year.

- Less heat entering the system, thus requiring a smaller cooling system.

- Lower noise levels.

- Reduced spending on hydraulic oil due to smaller oil reservoir.

- Increased life span of system oil.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.